Paʻa keleawe Kcr0.5 ikaika kiʻekiʻe

Hoʻolauna

Loaʻa i ka pā keleawe Chrome nā mea maikaʻi o ke kūpaʻa hoʻomaha hoʻomaha koʻikoʻi, ke kūpaʻa wela maikaʻi, ka conductivity uila maikaʻi, ke kūpaʻa corrosion maikaʻi, a me ka hana electroplating maikaʻi.He keleawe keleawe ka Chrome keleawe i loaʻa ka 0.4% a 1.1% Cr.Hiki ke hoʻoikaika ʻia ke keleawe Chrome e ka quenching-aging a i ʻole quenching-cold deformation-aging.Ma ka wela eutectic o 1072 °C, ʻo ka nui o ka solubility o ka chromium i ke keleawe he 0.65%.Me ka emi ʻana o ka mahana, ua emi loa ka solubility paʻa, a ua hoʻokahe ʻia ka māhele ʻāpana Cr e ka lāʻau ʻelemakule ma hope o ka hopena paʻa.

Nā huahana

Palapala noi

E hana i nā electrodes mīkini wiliwili, nā mīkini commutators a me nā ʻāpana ʻē aʻe e hana ana i nā wela kiʻekiʻe a koi aku i ka ikaika kiʻekiʻe, paʻakikī, conductivity a me ka conductivity.Aia ka mahana hana ma lalo o 350 ° C, a hiki ke hoʻohana ʻia ma ke ʻano o nā disc bimetallic no nā disc brake a me nā disc.ʻO kahi liʻiliʻi o ka waiwai (≤0.01) o ka zirconium i loaʻa i ka chrome bronze.Loaʻa i kēia maikaʻi uila conductivity, thermal conductivity, na hardness, wear resistance, explosion resistance, crack resistance at softening temperature, ʻoi aku ka maikaʻi o ka hoʻohana ʻana, a me ka helu helu helu o ka welding.He kūpono kēia no nā electrodes a me nā mea pili i ka mīkini fusion welding.

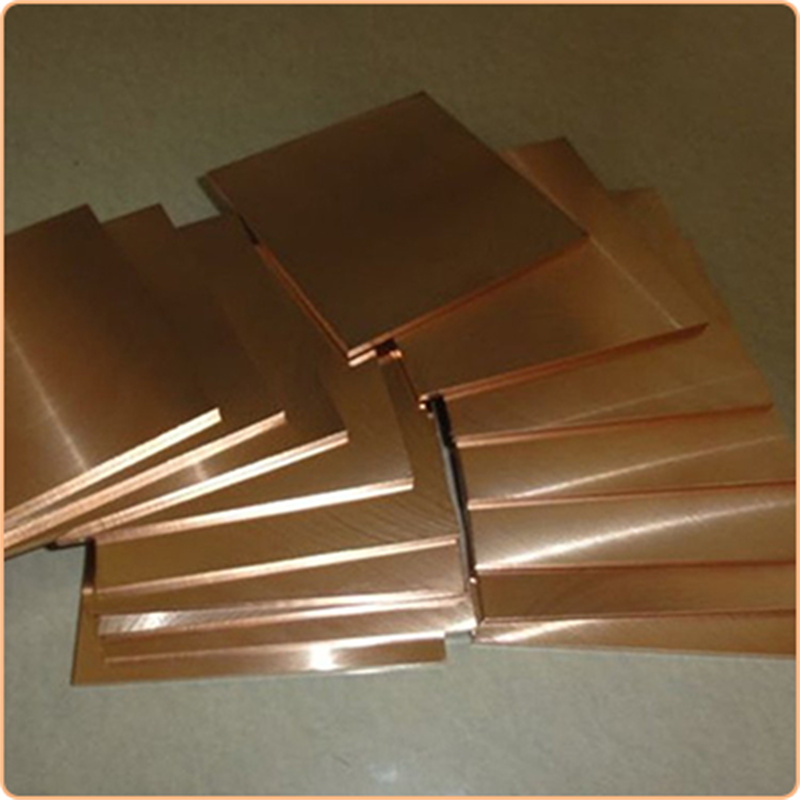

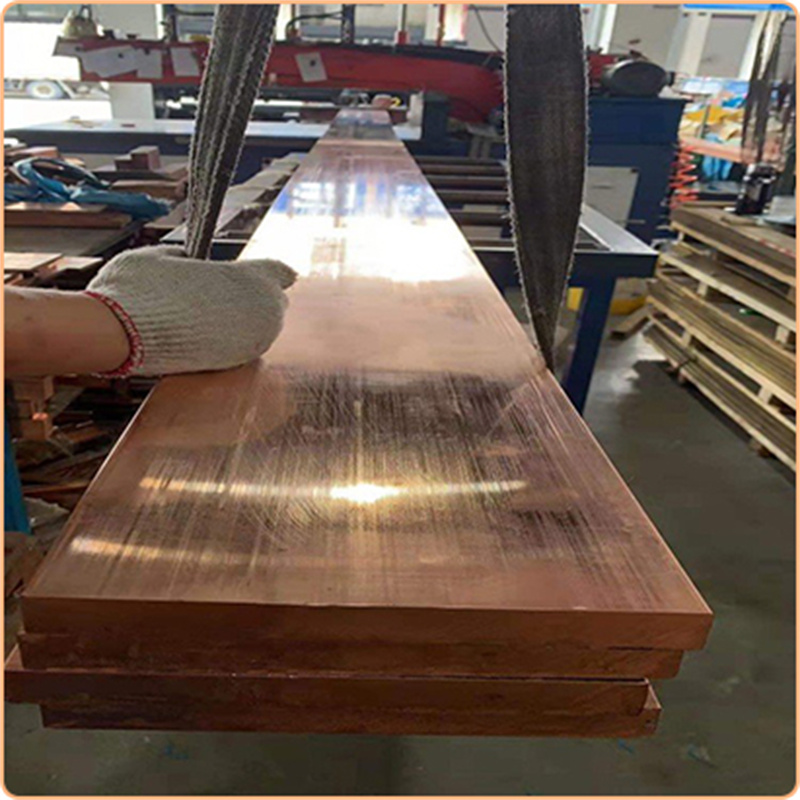

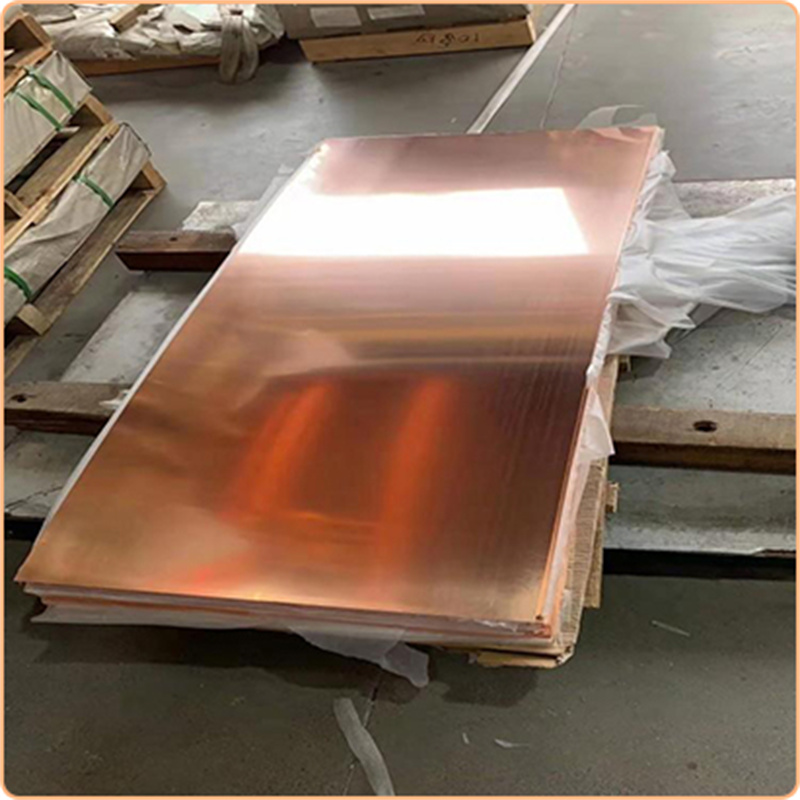

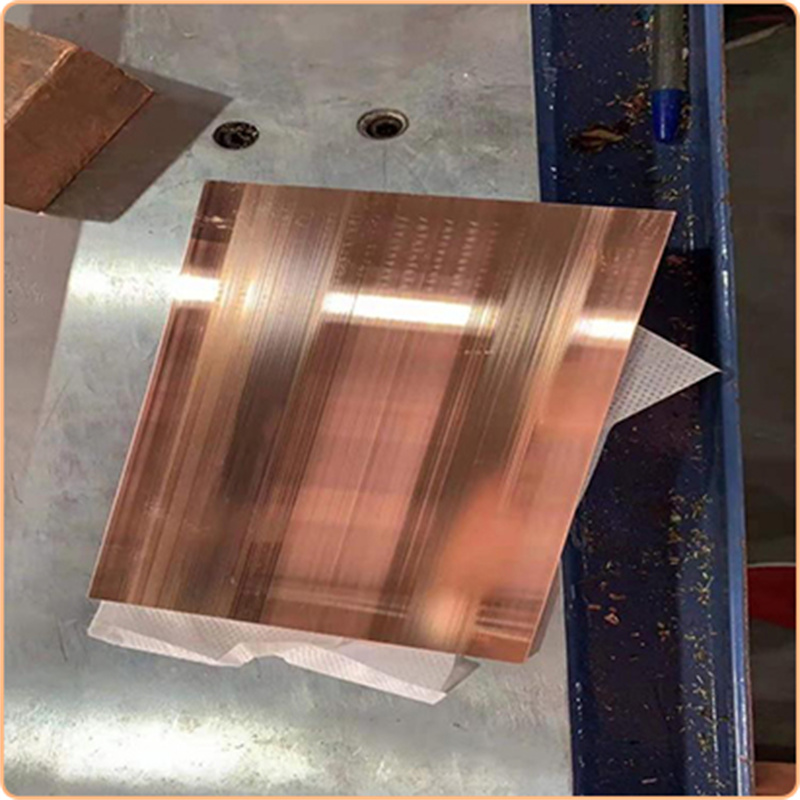

Hōʻike huahana

| 'ikamu | Kaha keleawe Zirconium |

| Kūlana | ASTM, AISI, JIS, ISO, EN, BS, GB, etc. |

| Mea waiwai | C18150, C18200, C18400, C18500 |

| Nui | mānoanoa: 0.1-200mm Laulā: 10-2000mm Length: hoʻopilikino ʻia a i ʻole ma ke noi Hiki ke hoʻololi i ka nui e like me ka makemake o ka mea kūʻai. |

| Ili | Mill, poni, ʻālohilohi, ʻaila, laina lauoho, palaki, aniani, pahū one, a i ʻole e like me ke koi ʻia. |